Drott 120, 120C Crawler Excavator Service Manual S406208M2 English

Brand: CASE Construction / Drott

Product Range: Crawler Excavator

Publication Type: Service Manual

Equipment Model: 120, 120C Crawler Excavator

Serial Number: -

Publication Number: S406208M2

Issued: Printed in U.S.A.

Language: English

Pages: 188

File Format: PDF Document

Additional Information: All components and systems are covered, with the exception of the engine which is covered in the engine manufacturer's manual. For Engine Repair, See the Engine Service Manual.

Introduction

This manual is designed to serve as a guide in maintaining and servicing the 120 CRAWLER. All components and systems are covered, with the exception of the engine which is covered in the engine manufacturer's manual.

The book is basically divided into five sections, preceded by a general section on safety. nomenclature and Parts & Service information.

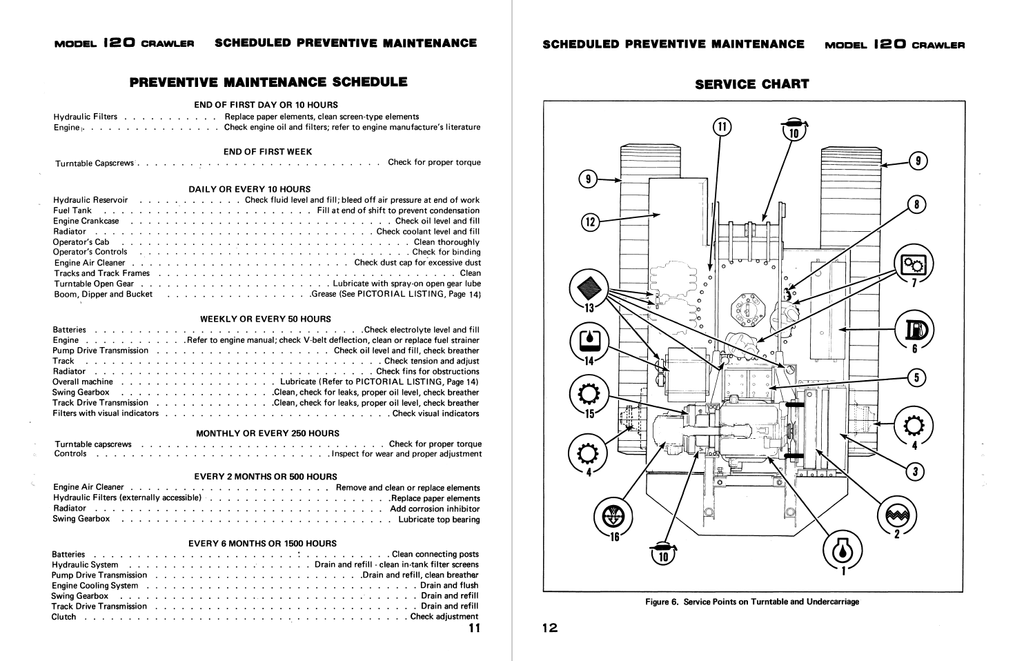

Section 1 gives the Scheduled Preventive Maintenance needed to keep the machine in top operating condition. It includes a maintenance schedule, component capacities, service chart, lubricant and fluid recommendations, and a pictorial listing of all grease fitting locations. If more detailed maintenance information is required, it can be found in the individual service sections.

Section 2 covers the undercarriage. It includes the turntable bearing, the tracks and the track drives.

Section 3 covers the mechanical components of the upperstructure. Included are the engine, pump drive transmission, the swing assemblies and the boom assembly.

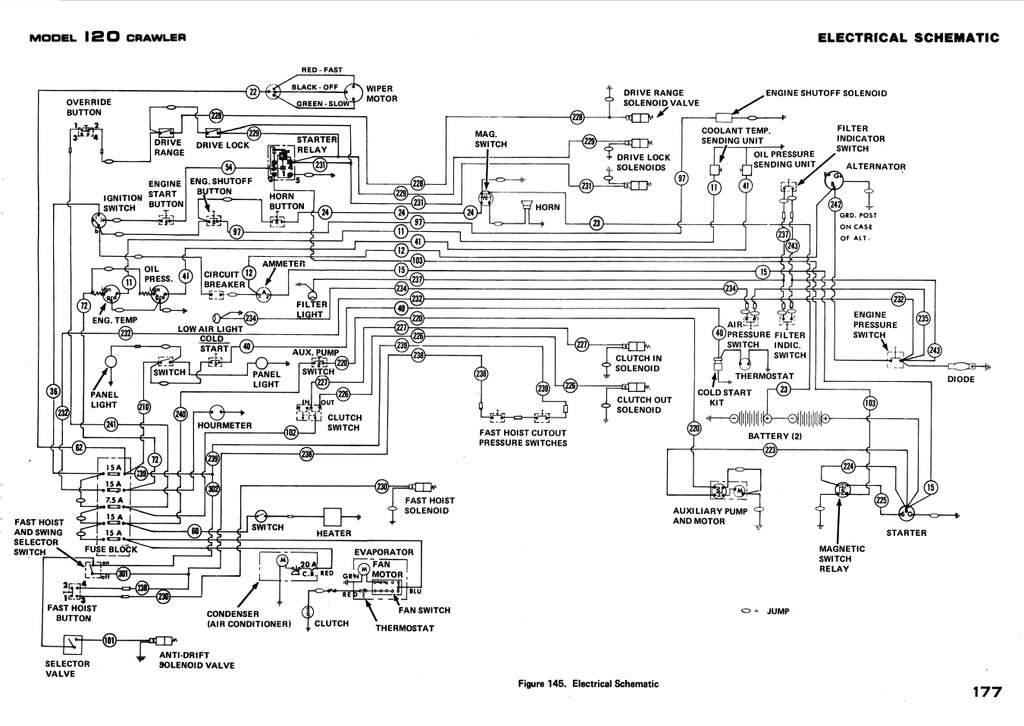

Section 4 covers the Electrical System. It is divided into the charging system, lights and instrument circuits, and the control circuits.

Section 5 covers the Hydraulic System. It includes the main system, the pilot control system, the counterweight system, the supercharge system, and the auxiliary hydraulic system.

The sections are divided into two subdivisions. The first part covers description, maintenance and troubleshooting. The second part covers disassembly and repair. Torque Charts and Schematics of the hydraulic and electrical systems are located in back of this manual. These should be used as aids in troubleshooting.

Table of Contents

GENERAL

Safety Precautions

Introduction

Nomenclature and Machine General Description

Directional Reference

Parts and Service

SECTION 1 - SCHEDULED PREVENTIVE MAINTENANCE

Lubricant and Fluid Recommendations

Component Capacities

Pressure Settings

Maintenance Schedule

Service Chart

Pictorial Listing of Grease Fitting Locations

SECTION 2 - THE UNDERCARRIAGE

Description, Maintenance and Troubleshooting

Carbody and Turntable Bearing

Track Assemblies

Track Drive Assemblies

Disassembly and Repair

General Cleaning Instructions

Upper Track Rollers

Lower Track Rollers

Idler Wheel Assembly

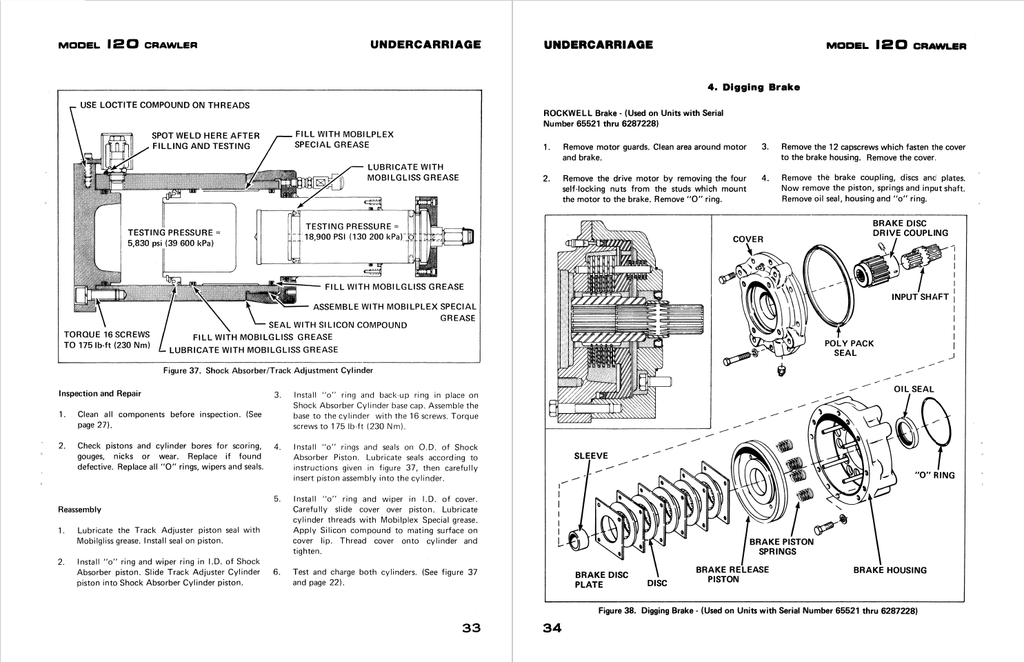

Digging Brake

Track Drive Transmission

SECTION 3 - THE UPPERSTRUCTURE

Description, Maintenance and Troubleshooting

Pump Drive System

Swing System

Boom Assembly

Disassembly and Repair

Pump Drive Transmission and Clutch

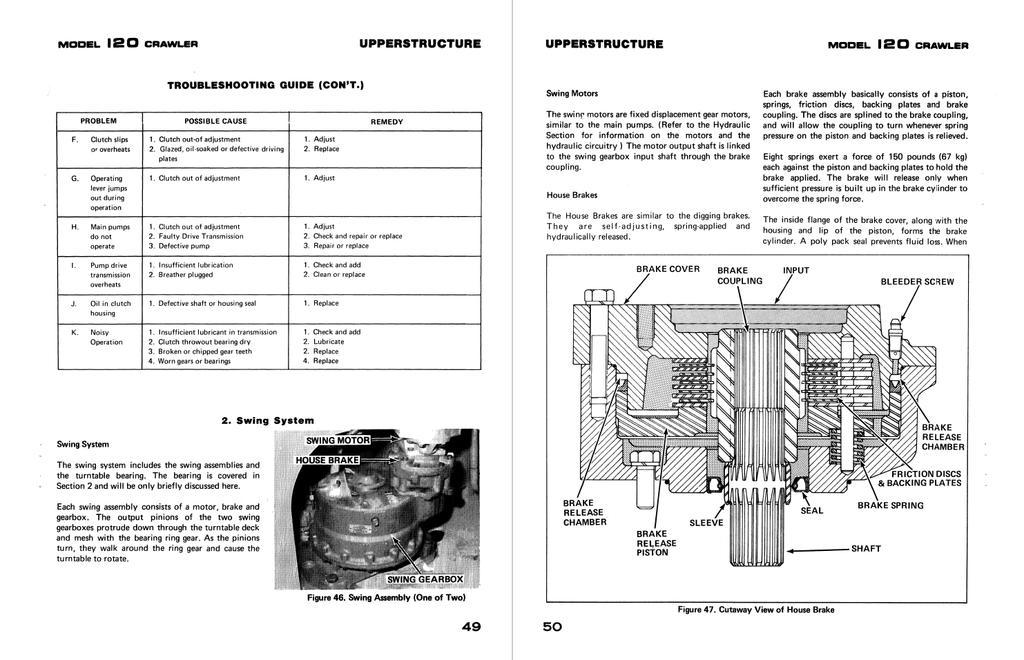

House Brakes

Swing Gearbox

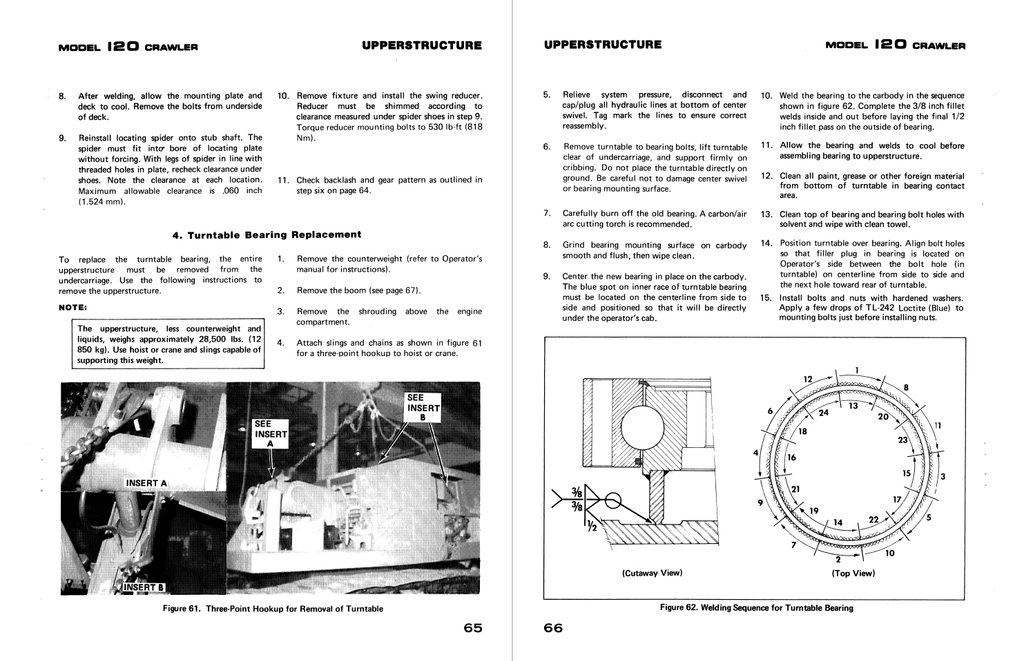

Turntable Bearing Replacement

Boom Removal

SECTION 4 - THE ELECTRICAL SYSTEM

Description, Maintenance and Troubleshooting

The Charging System

Control Circuits

Lights and Instrument Circuits

Disassembly and Repair

SECTION 5 - THE HYDRAULIC SYSTEM

Description, Maintenance and Troubleshooting

Introduction to Hydraulics

General Description and System Maintenance

Hydraulic Reservoir and Supercharge System

Hydraulic System Flushing and Troubleshooting

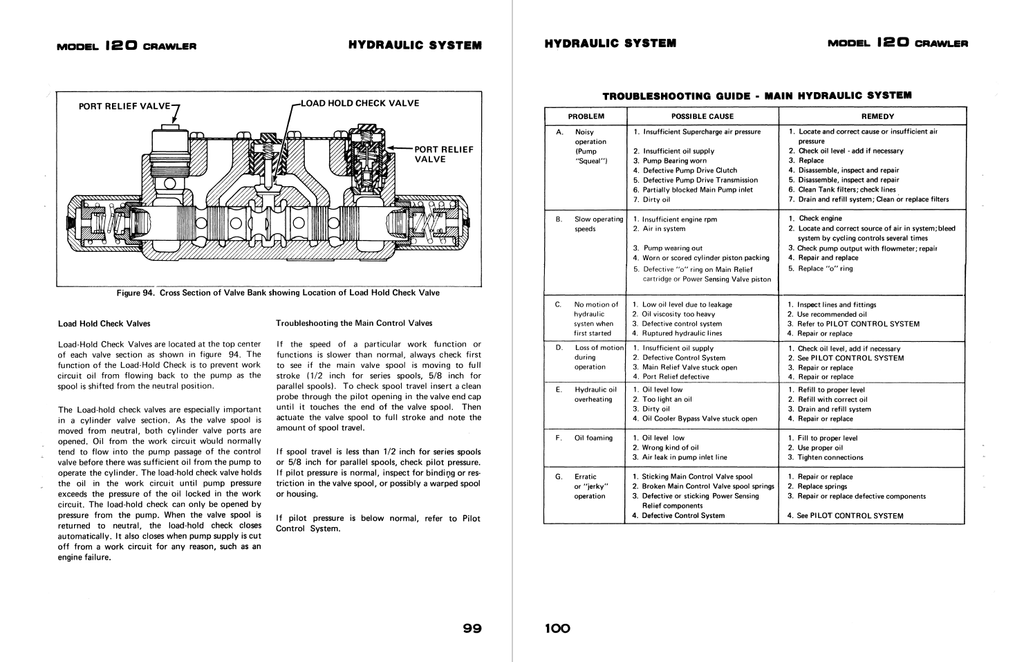

Main Hydraulic System

Pilot Control System

Auxiliary System

Track Drive Circuit

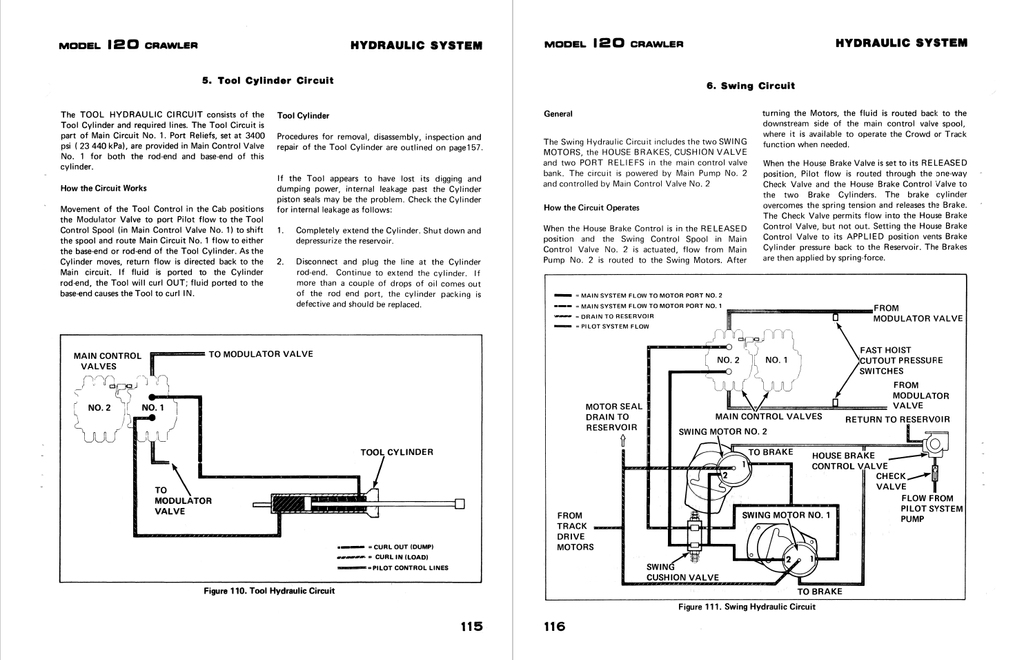

Tool Cylinder Circuit

Swing Circuit

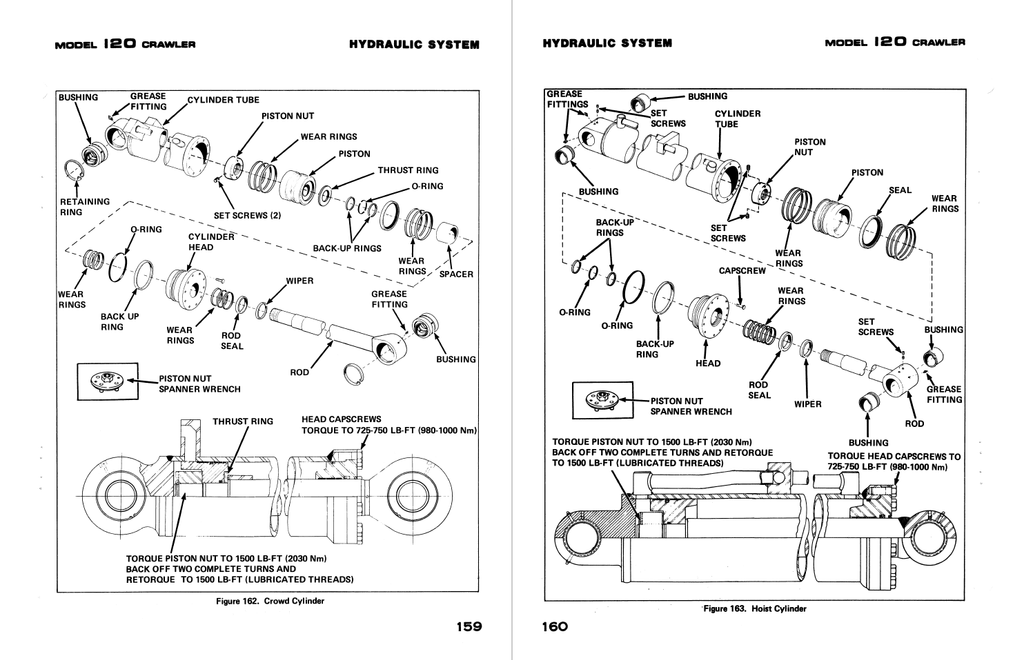

Crowd Cylinder Circuit

Hoist Cylinder Circuit (includes Fast Hoist Circuit)

Pump Drive Clutch Circuit

Counterweight System

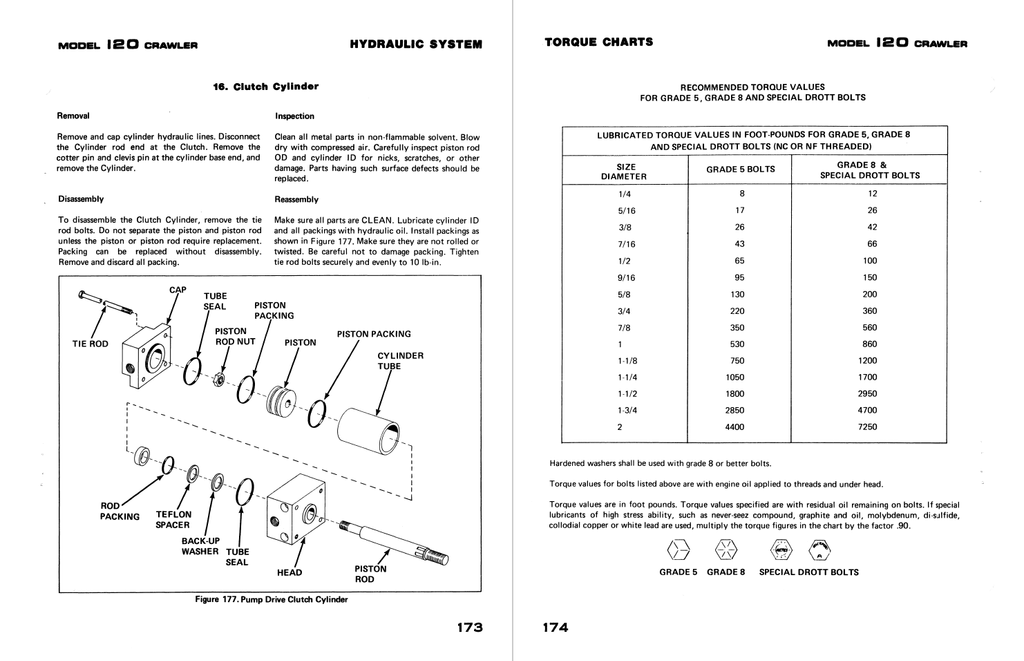

Disassembly and Repair

Hydraulic Reservoir

Main Pumps

Main Control Valves

Power Sensing Valve

Hydraulic Filters (In-line)

Charging Pump

Modulator Valves

Swing Cushion Valve

Swing Motors

Tool, Crowd and Hoist Cylinders

Fast Hoist Control Valve

Track Drive Motors

Hydraulic Swivel

Counterweight Control Valve

Counterweight Cylinders

Clutch Cylinder

TORQUE CHARTS AND SCHEMATICS